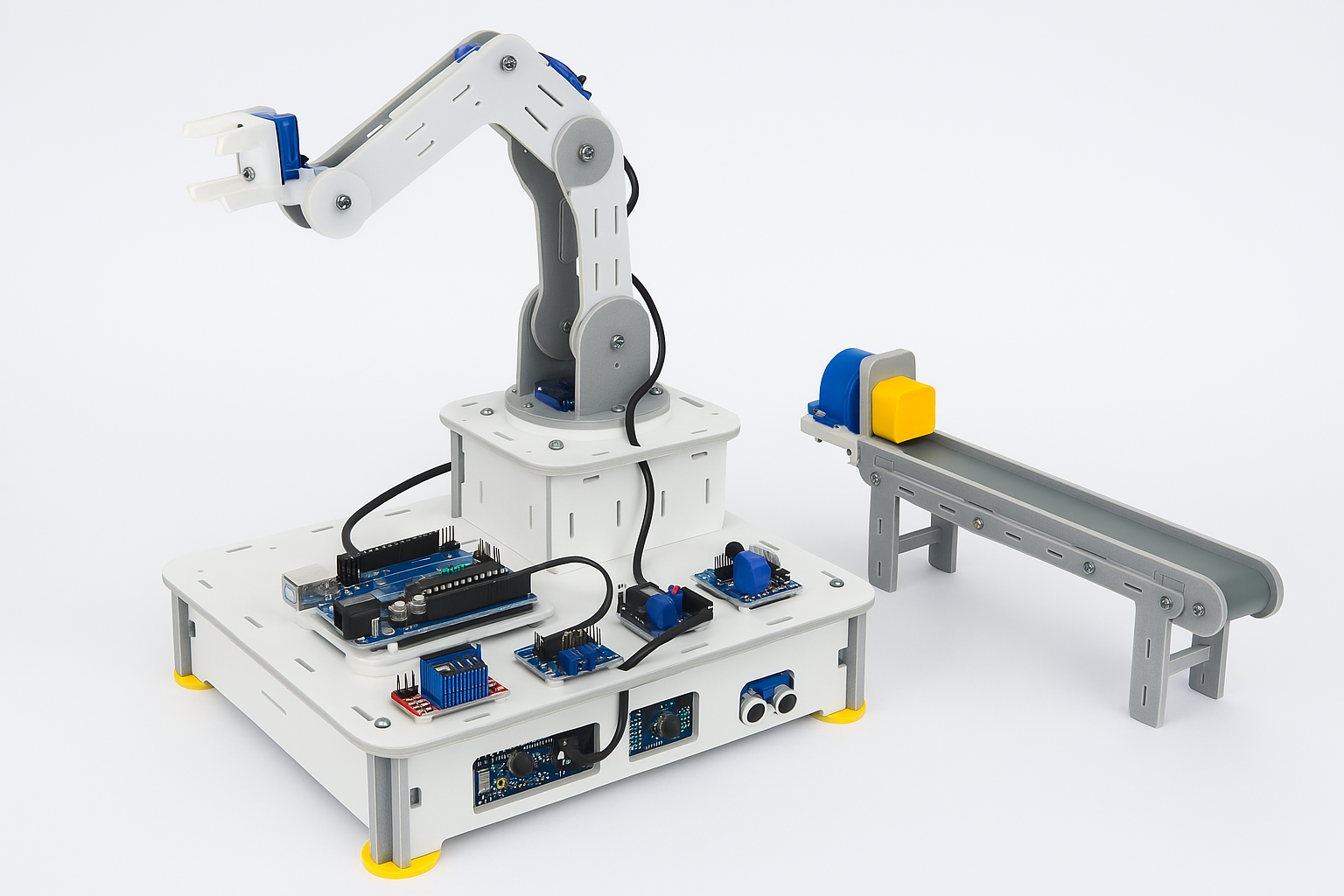

Smart Factory: Robotic Arm and Vision-Guided Sorting Conveyor

In this lesson, students explore the core concepts of industrial automation by building a mini smart factory cell. Using Arduino, sensors, cameras, and robotic components, they create a working model of a vision-guided sorting system — similar to the ones used in modern factories like Amazon or Tesla.

The project focuses on detecting, identifying, and sorting objects automatically based on color or shape, combining robotics, computer vision, and smart control systems.

Key Concepts Covered

- Basics of industrial robotics and mechatronics

- Computer vision for recognizing colors and shapes

- Using AI-style logic to sort objects into bins

- Controlling conveyor systems and robotic movement

- Real-world integration of sensors, actuators, and decision-making algorithms

Components Used

| Component | Purpose |

|---|---|

| DIY 4-DOF Robotic Arm (Arduino-based) | For picking and placing objects |

| TCS34725 / Adafruit APDS-9960 | Color detection and proximity sensing |

| Mini USB Camera / OpenMV Cam | Real-time image processing and object classification |

| IR or Ultrasonic Sensors | Detect object presence on conveyor |

| DC Motors + Motor Driver (L298N, etc.) | Drive the conveyor belt |

| Limit Switches / Rotary Encoders | Detect object position or track conveyor movement |

| Relay or Servo Mechanism | Control object binning and sorting arms |

How It Works

- Objects are placed on the moving conveyor.

- A sensor or camera detects the object and identifies its color or shape.

- The microcontroller processes this information and decides which bin the object should go to.

- The robotic arm or servo system moves the object to the correct bin.

- The system repeats the process, fully automated.

This setup mimics smart manufacturing environments where speed, accuracy, and automation are essential.

Learning Outcomes

- Build and program a simple automated factory cell using Arduino

- Understand how vision-guided systems are used in smart industries

- Learn to combine hardware (sensors, motors) and software (image processing, control logic)

- Gain experience in microcontroller-based automation and mechatronics

- Understand real-world applications in supply chains, sorting lines, and robotics

Optional Extensions

- Use OpenCV with Python on Raspberry Pi for more advanced image classification

- Integrate IoT dashboards for remote monitoring of conveyor stats

- Add a touchscreen or LCD display for operator control panel

- Design a feedback loop for improving sorting accuracy over time